The additives in wall putty,plaster,render,skim coat

-HPMC(hydroxypropyl methylcellulose/hypromellose)

-MHEC(methyl hydroxyethyl cellulose)

-RDP(redispersible polymer powder)

What is wall putty?

Wall putty is a kind of dry mix mortar products which is made of white cement mixed with other additives. It is applied to the wall to fill the cracks,imperfections, and gaps in the wall to create an even base for your paint. Normally wall putty means the plaster on interior wall.

Normally wall putty is packaged in bag and already mixed with the additives-HPMC, MHEC, RDP and other function materials, only need to add water and mix it when you use it. It is not necessary to add any other chemicals in it.

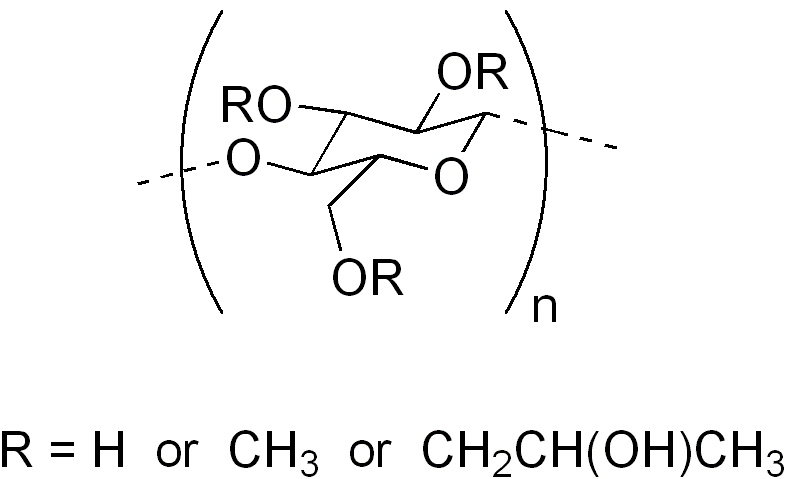

What is the role of HPMC-hydroxypropyl methyl cellulose and MHEC-methyl hydroxyethyl cellulose in wall putty?

HPMC or MHEC could provide the good water retention to make sure the cement and other additives fully hydrated. Increase the strength of wall putty and make sure the functions of all other additives in the fomulcation.

Sag-resistance: Choose the HPMC or MHEC with right viscosity can provide a good thickness of wet mortar, prevent wall putty sagging.

HPMC or MHEC have the good filming property on the surface of wall putty, it could reduce the water absorption of the base wall, reduce the risk of cracking.

Increase the workability.

HPMC and HPMC specifications used in wall putty, plaster, render, skim coat.

| Mailose MP/ME60K | Mailose MP/ME 100K | Mailose MP/ME150K | Mailose MP/ME 200K |

Appearance | White powder | White powder | White powder | White powder |

Moisture | 5% Max. | 5% Max. | 5% Max. | 5% Max. |

Ash content | 5% Max. | 5% Max. | 5% Max. | 5% Max. |

Viscosity NDJ-1,2% solu.20℃ | 48000-72000cps | 80000-120000cps | 120000-180000cps | 180000cps Min. |

Particle size | 95% pass 100 mesh | 95% pass 100 mesh | 95% pass 100 mesh | 95% pass 100 mesh |

Package: 25 kgs per bag with pp or pe inner

20 feet container can load 12 tons with pallets or 14 tons without pallets

40 feet container can load 24 tons with pallets or 26 tons without pallets

What is the function of RDP-redispersible polymer powder in wall putty, render, plaster, skim coat?

Maissen redispersible polymer powder is based on vinyl acetate ethylene copolymer and used PVA as the protection clloid. Could disperse in water very well and form the emulsion.

Choose right specification of RDP-redispersible polymer powder in wall putty could increase the bonding strength, workability and flexibility. Meanwhile increase the water proofing property of the products.

RDP-redispersible polymer powder specifications used in wall putty, plaster, render, skim coat.

| Appearance | solid content | Ash content | Average particle size | Minimum fil-forming temperature | TG |

Maissen RDP 707U | Whit powder, free-flowing

| 99% Min. | 12±2% | ~80μm | 0℃ | 3℃ |

Maissen RDP 730T | Whit powder, free-flowing | 99% Min. | 12±2% | ~80μm | 4℃ | 12℃ |

Package: 25kgs per bag with pp or pe inner

Jinan maissen new material co.,ltd is the major manufacturer of cellulose ether and redispersible polymer powder in China. Supply:

-HPMC(hydroxypropyl methylcellulose/hypromellose)

-MHEC(methyl hydroxyethyl cellulose)

-RDP(redispersible polymer powder)

-Other chemical additives in dry mix mortar industry

Email: info@mailose.com

Whatapp:+86 17731143133

Key words: HPMC, MHEC, RDP, cellulose ether, wall putty, plaster, render, skim coat, construction chemicals, additives.