Dry mix mortar raw material and composition

Introduction:

There are many types of dry-mix mortar, and its composition is also more complicated. To produce dry-mixed mortar, local mineral resources should be used as much as possible. The raw materials are generally as follows:The gel material uses cement, gypsum, lime, etc. The main aggregates are river sand, quartz sand, machine-made sand, limestone, dolomite, perlite, etc. Mineral admixtures are mainly industrial by-products, industrial wastes and some natural ores, such as slag, fly ash, pozzolan, fine silica powder. Main additives includes construction grade cellulose ether HPMC and MHEC as the water retention agent and other dry mix mortar additives, for example: RDP-redispersible polymer powder, PCE, PVA etc.

1.Classifiy of dry mix mortar raw materials

Gel materials | Ordinary Portland Cement

Sulphoaluminate cement

Special cement

Lime

Gypsum |

Aggregates

| River sand

Quartz sand

Machine-made sand,

Limestone

Dolomite perlite

|

Mineral admixtures

| Slag

Fly ash

Pozzolan

Fine silica powder

Calcium carbonate |

Additives | Construction grade cellulose ether

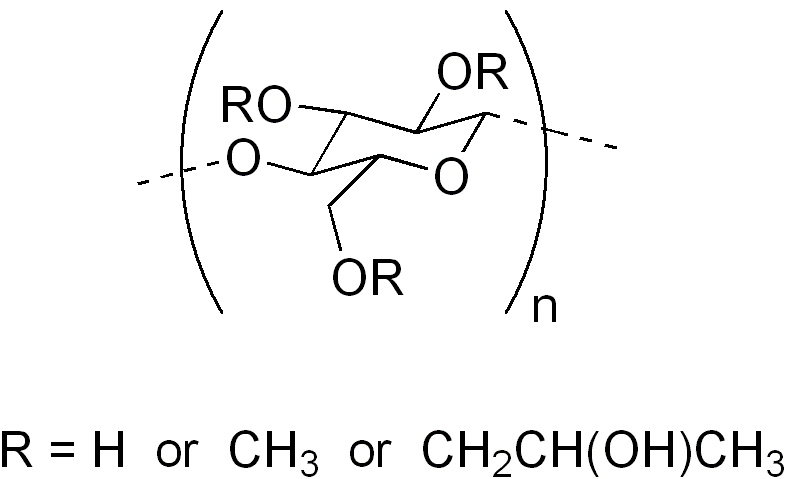

HPMC-hydroxypropyl methylcellulose

MHEC-Methyl hydroxyethyl cellulose

Redispersible polymer powder

Starch ether HPS

PP fiber

PCE

Calcium formate

...... |

2.Functions of the raw materials of dry mix mortar

Gel materials | Cement: powdery hard inorganic gel material, which forms a slurry after mixing with water, which can harden better in water, and can firmly cement sand, stone and other materials together.

Lime: an air-hardening inorganic gel material that condenses and hardens in the air. Good plasticity, but large volume shrinkage and poor water resistance.

Gypsum: Air-hardening inorganic gel material, fast setting and hardening, light weight, but poor water resistance and frost resistance.

|

Aggregates

| Sand and gravel aggregates act as a skeleton in the mortar to transmit stress, while restraining shrinkage and preventing cracking.

|

Mineral admixtures

| The admixture is an inorganic material added to the mortar to improve the workability of the mortar. It can replace part of the cement. It can not only reduce the cost, but also improve the workability of the mortar, increase the air permeability, reduce the heat of hydration, and reduce Particle separation reduces shrinkage and cracking of the mortar.

|

Additives

| Addtivies is very important to the function and quality of the dry mix mortar products.

Construction grade cellulose ether HPMC and MHEC is a basic and important additives in dry mix mortar products. Could adjust the setting and provide high performance of water retention, make sure all the additives and cement have enough water to reach the best performance. Meanhile choose right grade cellulose ether HPMC and MHEC could reduce the risk of craking and increase the workability.

|

3.Important additives - construction grade cellulose ether HPMC , MHEC and RDP in dry mix mortar

Dry mix mortar additives | Functions |

Construction grade cellulose ether HPMC-hydroxypropyl methyl cellulose MHEC-Methyl hydroxyethyl cellulose | Increase bonding strength between mortar and the surface base. Increase the workability Increase water retention Anti-Craking Anti-slip Adjust the setting time Stability |

Redispersible polymer powder | Good flexibility Improve workability Reduce water absorption Increase adhesion strength |

Jinan maissen new material co.,ltd is the major cellulose ether and redisperisble polymer powder manufacturer in China. Supply high quality construction grade cellulose ethers:HPMC,MHEC and Redispersible polymer powder.

info@mailose.com

www.maissen-hpmc.com